Hard Water, Minerals, and Accelerated Pipe Corrosion: Protection Strategies

Hard water, rich in calcium and magnesium, significantly contributes to pipe corrosion, accelerating…….

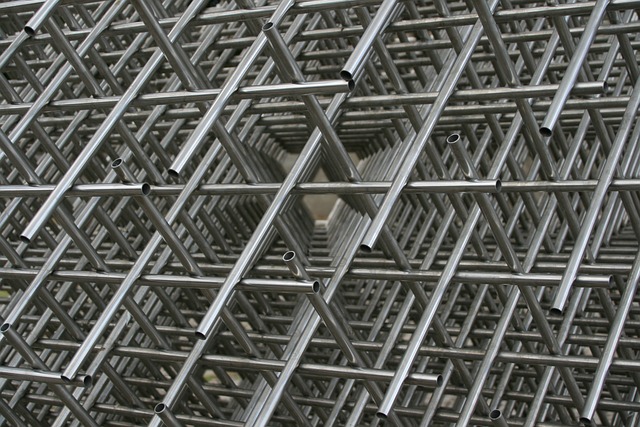

Pipe corrosion, a silent yet pervasive menace, poses significant challenges across industries, from water distribution networks to oil and gas transportation. This phenomenon, characterized by the degradation and erosion of pipes’ structural integrity due to chemical reactions, has far-reaching implications. The ‘Common Causes of Pipe Corrosion’ is a comprehensive exploration of the multifaceted factors contributing to this issue, offering valuable insights for professionals, researchers, and policymakers. By delving into these causes, we aim to enhance understanding, drive innovation, and foster sustainable practices in an effort to mitigate corrosion’s detrimental effects.

Pipe corrosion, a complex process, is primarily driven by the interaction between a metal pipe’s surface and its surrounding environment. This phenomenon involves several interconnected factors, including chemical, electrochemical, and environmental influences. Over time, these interactions lead to the formation of corrosion products, such as rust or oxide layers, which weaken the pipe’s structural integrity, leading to leaks, bursts, and reduced lifespan.

Core Components:

Metal Type: Different metals exhibit varying susceptibility to corrosion. For instance, iron and steel are highly susceptible due to their inherent chemical composition, while copper and some stainless steels have better resistance.

Corrosive Environment: The surrounding environment plays a pivotal role. Factors like moisture, humidity, temperature extremes, salt water, acidic or alkaline substances, and the presence of corrosive gases can accelerate corrosion rates.

Electrochemical Reactions: These reactions occur when metal pipes act as an electrical conductor in a circuit, often facilitated by the presence of contaminants or moisture. The flow of electrons at the interface between the pipe and its environment leads to localized corrosion, which, if unchecked, can spread and weaken the pipe.

Mechanical Stress: Pre-existing cracks, seams, welds, or imperfections in the pipe’s structure can act as initiation sites for corrosion. Mechanical stress, especially under pressure, exacerbates these points of weakness, leading to accelerated degradation.

The impact of common causes of pipe corrosion is not limited by geographical boundaries. It transcends national borders, affecting every region with infrastructure reliant on metal pipes. However, the severity and specific trends vary across different parts of the globe:

| Region | Key Trends and Observations |

|---|---|

| North America | High prevalence in aging water distribution systems, especially in urban areas. Rising costs of pipe replacement and maintenance are a significant concern. |

| Europe | Stringent environmental regulations drive the adoption of corrosion-resistant materials and innovative coating technologies. The energy sector faces challenges due to corrosive gases in pipeline systems. |

| Asia Pacific | Rapid urbanization leads to increased demand for pipe infrastructure, exposing new networks to corrosion risks. The region witnesses a surge in investments for smart and corrosion-resilient pipes. |

| Middle East & Africa | High temperatures and desert environments accelerate corrosion rates. There’s a growing focus on corrosion protection for offshore oil and gas pipelines. |

| Latin America | Limited access to advanced corrosion prevention technologies, coupled with unpredictable weather patterns, poses unique challenges. |

The economic implications of common causes of pipe corrosion are profound, impacting various sectors differently:

Water Treatment and Distribution: Regular maintenance and premature replacements drive up operational costs. According to a 2022 report by the Global Market Insights, the global water infrastructure market is projected to exceed $1.5 trillion by 2030, largely due to corrosion-related issues.

Oil and Gas: Corrosion in pipelines results in significant losses, including product spills, downtime for repairs, and reduced transportation efficiency. The American Petroleum Institute (API) estimates that pipe corrosion accounts for over 30% of major pipeline failures globally.

Energy Generation: In power plants, corrosion in boilers and heat exchangers can lead to efficiency losses, increased maintenance costs, and potential safety hazards.

Infrastructure Development: New pipe installations require careful material selection and design considerations to mitigate corrosion risks, adding to the overall project cost.

The quest for effective pipe corrosion prevention has spurred numerous technological breakthroughs:

Advanced Coatings: Electrochemical, polymeric, and zinc-rich coatings offer powerful barriers against corrosion. For instance, epoxy coatings with built-in corrosion inhibitors have proven effective in marine environments.

Smart Pipes: Incorporating sensors and monitoring systems into pipes allows for real-time data on environmental conditions and pipe health, enabling proactive corrosion management.

Material Science Innovations: Newer alloys and composite materials are designed to resist corrosion, offering lighter alternatives to traditional metals in certain applications.

Non-Destructive Testing (NDT): Techniques like ultrasonics, magnetic particle inspection, and eddy current testing help identify corroded areas without causing damage, enabling targeted maintenance.

A major city’s water utility authority faced severe corrosion issues in its aging cast iron pipe network, leading to frequent leaks and water quality concerns. They implemented a comprehensive strategy:

Pipe Lining: They used an epoxy-based pipe lining system to create a new, smooth inner surface, reducing the corrosion site.

Coated Steel Pipes: For new installations, they adopted zinc-rich galvanization and protective coatings, ensuring long-term resistance.

Real-Time Monitoring: Smart sensors were deployed to continuously monitor pH levels, temperature, and pressure, enabling early detection of potential corrosion hotspots.

Regular Maintenance: Routine inspections and maintenance programs identified and addressed issues before they became critical.

After two years, the utility authority reported a significant reduction in main breaks and improved water quality, resulting in substantial cost savings and enhanced customer satisfaction.

Policymakers worldwide are recognizing the urgency of addressing pipe corrosion, leading to various regulatory interventions:

Material Standards: Organizations like ASTM International and ISO set standards for corrosion-resistant materials, ensuring consistent quality in pipe production.

Pipeline Safety Regulations: Authorities mandate regular inspections, maintenance, and corrosion protection measures for critical infrastructure, such as oil and gas pipelines.

Environmental Compliance: Stringent environmental regulations prompt industries to adopt more eco-friendly practices, including the use of less corrosive materials and innovative coating technologies.

Ongoing research in pipe corrosion prevention encompasses various avenues:

Nanotechnology: Nanomaterials with unique properties are being explored for their potential in enhancing corrosion resistance and self-healing capabilities.

Biological Corrosion Inhibitors: Scientists investigate the use of bacteria and biofilms to inhibit corrosion, offering a natural alternative to chemical inhibitors.

Predictive Modeling: Advanced computational models aim to predict corrosion behavior, enabling more effective design and maintenance strategies.

Common causes of pipe corrosion represent a complex global challenge that demands a multi-faceted approach. By understanding the underlying factors, embracing technological advancements, and implementing robust regulatory frameworks, industries can significantly reduce corrosion’s impact. Continuous research, coupled with industry collaboration, will drive innovation, ensuring more sustainable and resilient infrastructure for future generations.

Hard water, rich in calcium and magnesium, significantly contributes to pipe corrosion, accelerating…….

Rust, an outward sign of corrosion, forms when metal pipes react with mineral-rich water, weakening…….

Pipe corrosion, driven by water reactions causing oxidation or chemical breakdowns, leads to extensi…….

The text discusses galvanic corrosion, a significant plumbing issue caused by metal contact and elec…….

Pipe corrosion, driven by moisture intrusion, chemical impurities, and environmental factors, leads…….

Pipe corrosion, a significant issue, is caused by interactions between metal pipes and elements like…….

Pipe corrosion, a complex plumbing issue, arises from various internal and external factors. High mi…….

Pipe corrosion, driven by electrochemical processes, is accelerated by environmental factors such as…….

Pipe corrosion, an electrochemical process accelerated by moisture and aggressive substances, is cau…….

Moisture, contaminant buildup, improper drainage, hard water, standing water, and bacterial growth a…….