Hard water, rich in calcium and magnesium, significantly contributes to pipe corrosion, accelerating rust formation through galvanic reactions with metal pipes. This leads to structural damage, costly repairs, and reduced pipeline lifespan. To combat common causes of pipe corrosion, implement regular maintenance checks for early detection, apply corrosion-inhibiting coatings, choose durable materials like stainless steel, and ensure adequate treatment to prevent mineral buildup on pipe surfaces.

In many industrial settings, hard water and minerals are often seen as mere nuisances. However, these elements play a significant role in accelerating pipe corrosion, one of the common causes of pipeline failure. Understanding how hard water and minerals interact with pipes is crucial for maintaining efficient systems. This article delves into the mechanisms behind pipe corrosion, explores their complex relationship, and offers strategies to protect critical pipelines from premature deterioration.

- Understanding Pipe Corrosion: The Basic Mechanisms

- Hard Water and Minerals: A Complex Relationship with Pipes

- Mitigating the Impact: Strategies to Protect Your Pipelines

Understanding Pipe Corrosion: The Basic Mechanisms

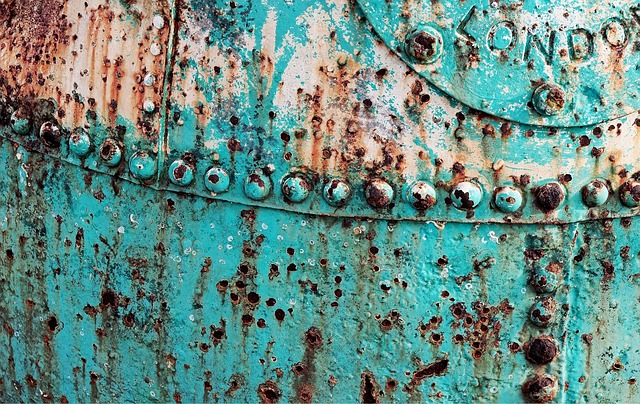

Pipe corrosion is a multifaceted issue driven by various factors, among which hard water and mineral content are notable contributors. Understanding the basic mechanisms behind pipe corrosion offers valuable insights into why these elements accelerate the deterioration process. Corrosion begins when metal pipes come into contact with oxygen and moisture, leading to the formation of rust, especially in the presence of salt or acid. This initial stage, known as oxidation, paves the way for further damage.

Common causes of pipe corrosion include water’s mineral content, such as calcium and magnesium (hardness), which can create a conductive environment, facilitating the transfer of electrons and speeding up corrosion. Over time, these minerals build up on pipe surfaces, forming scales that not only impair water flow but also serve as a protective barrier, preventing the application of effective corrosion-inhibiting coatings. Consequently, pipes become more susceptible to pitting, cracking, and eventual failure.

Hard Water and Minerals: A Complex Relationship with Pipes

Hard water, rich in minerals like calcium and magnesium, often presents a complex challenge for pipe maintenance. While these minerals are essential for various applications, they can also act as catalysts for accelerated pipe corrosion when in contact with metal pipes over time. The issue arises from a chemical reaction where the minerals in hard water react with the metal surface, leading to the formation of rust and other corrosions products. This process, known as galvanic corrosion, is one of the common causes of pipe corrosion, especially in regions with high mineral content in their water supplies.

The problem is exacerbated when pipes are not properly treated or coated to protect them from these natural elements. As hard water flows through the pipes, it leaves behind mineral deposits, further weakening the protective coatings and increasing the risk of corrosion. This can result in significant structural damage over time, leading to costly repairs and maintenance. Understanding this intricate relationship between hard water, minerals, and pipe corrosion is crucial in developing effective strategies to mitigate these issues and prolong the lifespan of piping systems.

Mitigating the Impact: Strategies to Protect Your Pipelines

To mitigate the impact of hard water and mineral-laden pipes, several strategies can be employed to protect your pipelines from common causes of pipe corrosion. One effective approach is regular maintenance checks. By scheduling routine inspections, you can identify early signs of corrosion, pitting, or other damage. This proactive measure allows for timely repair or replacement, preventing further deterioration.

Additionally, using corrosion-inhibiting coatings and linings on pipes can significantly extend their lifespan. These protective layers create a barrier between the pipe’s surface and corrosive elements, slowing down or stopping the corrosion process. Choosing the right materials for your pipeline infrastructure, such as stainless steel or coated metals, can also be an effective long-term solution to combat hard water and mineral-related corrosion.

Hard water and minerals, while essential for life, can become catalysts for pipe corrosion when not managed properly. Understanding how these elements interact with pipes is crucial in identifying the common causes of pipe corrosion. By implementing effective mitigation strategies, such as water treatment and regular inspection, you can significantly extend the lifespan of your pipelines, ensuring efficient and safe transportation of fluids. Remember, proactive measures are key to navigating the challenges posed by hard water and minerals, ultimately fostering a robust and sustainable infrastructure.